Theory of Constraints

The Theory of Constraints (TOC) is a body of knowledge that has been developed over the past twenty years by Dr Eliyahu Goldratt.

This body of knowledge challenges many of the assumptions about how we currently manage our businesses and organizations.

It is based on the logic of cause and effect and has been derived from the hard sciences. An approach to Process Improvement – can be used with or like JIT, MRP, etc.

Where do we start ?

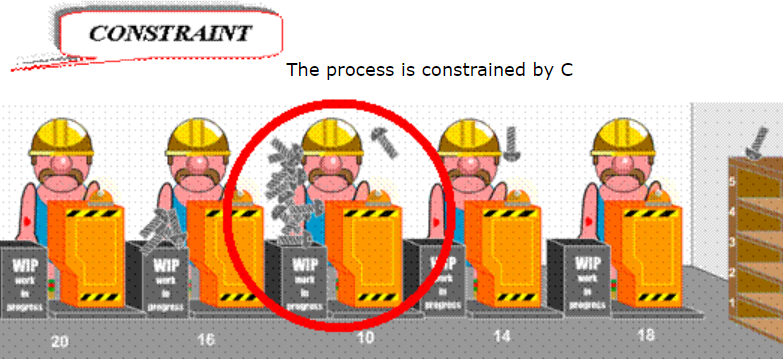

Every real system, such as a business, must have within it at least one constraint. If this were not the case then the system could produce unlimited amounts of whatever it was striving for, profit in the case of a business.……………….”

Dr Eli Goldratt

Concept :

TOC looks at a business’ operation as water flowing through a pipe.

&

The speed of the flow is a function of the diameter of the pipe and the pressure behind it.

2. A B C E (The size of the letter denotes the size of its capacity)

The process that causes the constraint, according to the TOC, impacts every process and function in the business from inputs to outputs.

E.g. accounting, marketing, sales, etc.

According to the TOC the major focus for any operation should be increasing the throughput of the organization – i.e., increasing the systems contribution to company sales. All other measures have little relevance to the overall effectiveness of the system.

Fundamental Guidelines of TOC :

- * An optimal system is not necessarily the sum of local optima. I.E., sub-optimization of each work center does not mean you have optimized the overall process.

- * Systems are like a chain and their strength is determined by the weakest link.

- * Knowing what to work on requires you to know the entire system and its goals.

- * Pareto was right – 80% of the problems are a result of 20% of the activities

- * Core problems (i.e., the root causes) are very seldom obvious. So if it appears that the problem is obvious, keep looking.

- * If you don’t find the root cause, you will have a false sense of security, i.e., the problem will be back to bite you again.

- * Constraints aren’t always physical; sometimes they are the result of bad policy and/or organization, e.g. vested interests.

- * Ideas may be the source of good solutions, but only action solves problems.

- * Focus needs to be on having a balanced flow through the system.

- * Non-bottlenecked activities should be redesigned/revamped to support those activities that are bottlenecked (constrained).

- * If an activity is producing something, but it isn’t addressing the constraints, then while it may be utilized, it isn’t helping things get better.

- * The slowest activity determines the maximum throughput of the system.

- * Don’t worry or fret over time lost in a non-constrained activity. It doesn’t have a significant impact on the system.

- * The amount transferred from Activity A to Activity B doesn’t have to be the amount that Activity A produced. Only over an amount that will reduce the constraining area, and generally this is less than what was produced.

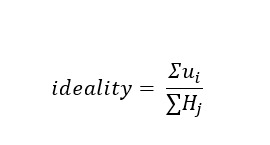

TRIZ :

TRIZ is an acronym for Russian “Teoriya Resheniya Izobretatelskikh Zadatch, which means “Theory of Inventive Problem Solving”. An inventive problem is defined as one in which the solution causes another problem to appear. Inventive problems stem from several contradictions. It is developed by Genrich Altshuller. It is a systematic approach for breakthrough solutions to tough-nut problems based on finding a creative solution if one is possible.

TRIZ inventive principles and the historical study of great inventions teach us that direct confrontation and resolution of contradictions are the keys to breakthrough inventions and ideas. It aims at creating an algorithmic approach to the invention of new systems and refinement of old systems.

The theory of invention should satisfy the following conditions.

- * Be a systematic, step-by-step procedure.

- * Be a guide through a broad solution space to direct to the ideal solution.

- * Be repeatable and reliable and not dependent on psychological tools.

- * Be able to access the body of inventive knowledge.

- * Be able to add to the body of inventive knowledge.

The process steps of TRIZ are:

|

The tools developed by Altshuller are:

| » | 40 inventive principles |

| » | 39 parameters |

| » | Algorithm of Inventive Problem Solving |

| » | Separation Principles |

| » | Substance-Field Analysis |

| » | Standard Solutions |

| » | Natural Effects |

| » | Patterns of Evolution |

Benefits of TRIZ :

| » | Development of a structured, systemic thinking |

| » | Ability t control one thought process |

| » | Ability to easily break psychological inertia |

Ability to perform unusual mental operations

Business Process Reengineering is defined as the fundamental rethinking and radical redesign of business processes to achieve dramatic improvements in critical contemporary measures of performance, such as cost, quality, service and speed (Hammer and Champy). Business Process Reengineering can be considered as a combined application of theories and concepts from mainly three areas, viz., Marketing, Organization Theory and Informatics.

|

|

The main elements of BPR are:

| » | Strategies, which cover the areas under concern-e.g.organization strategy, technology strategy, and human resources strategy |

| » | Processes-identify processes which are satisfying customer needs |

| » | Technology-IT, new technologies and technological changes and methods. |

| » | People |

How to implement a BPR project:

The best way to map and improve the organization's procedures is to take a top down approach, and not undertake a project in isolation. That means:

| » | Starting with mission statements that define the purpose of the organization and describe what sets it apart from others in its sector or industry. |

| » | Producing vision statements which define where the organization is going, to provide a clear picture of the desired future position. |

| » | Build these into a clear business strategy thereby deriving the project objectives. |

| » | Defining behaviours that will enable the organization to achieve its' aims. |

| » | Producing key performance measures to track progress. |

| » | Relating efficiency improvements to the culture of the organization |

| » | Identifying initiatives that will improve performance. |

There are several reasons for organizations to reengineer their business processes:

| » | To re-invent the way they do work to satisfy their customers; |

| » | To be competitive; |

| » | To cure systemic process and behavioral problems; |

| » | To enhance their capability to expand to other industries; |

| » | To accommodate an era of change; |

| » | To satisfy their customers, employees, and other stakeholders who want them to be dramatically different and/or to produce different results |

| » | To survive and be successful in the long term; and |

To invent the "rules of the game."

Supply Chain Management :

Supply Chain Management is the process of planning, implementing and controlling the operations of the supply chain as efficiently as possible. Supply chain management spans all movement and storage of raw materials, work-in-process inventory, and finished goods from point-of-origin to point-of-consumption. Supply Chain Management integrates supply and demand management within and across companies. The ultimate goal of any effective supply chain management system is to reduce inventory (with the assumption that product are available when needed)

Supply chain management addresses problems of distribution network, distribution strategy, information, inventory management and cash flow. Successful SCM requires a change from managing individual functions to integrating activities into key supply chain processes.

Organizations increasingly find that they must rely on effective supply chains, or networks, to successfully compete in the global market and networked economy.

The key components of SCM are:

- Plan

- Procure

- Produce

- Store

- Ship

- Service

Supply chain management flows can be divided into three main flows:

- The product flow

- The information flow

- The finances flow

Effective supply chain management solves many of the problems encountered by businesses. The vendors involved in the chain will actually have a clearer idea of what the buyer needs and can then adequately provide for these needs. Slow response times and delays in project start dates also become less frequent because the automated supply chain helps shave the time off of the order placement and fulfillment process.

This course in an introduction to the supply chain concept and will explore the management of supply chains to improve an organization’s overall capacity. The concepts included are identification procedures, methods, processes and systems that are used to improve the operation of supply chain.

The course is beneficial in imparting comprehensive knowledge of critical role supply chain management. The students learn increasing customer value and how supply chain

management can support marketing strategies. The course is beneficial for the organizations in managing multiple supply chains and also to achieve sustainable competitive advantage.

Operations Research :

Operations Research started in 1930’s in UK started as integration of radar data with ground based observer data for fighter interception by British Air Ministry.

Operations Research is an interdisciplinary branch of mathematics, which uses methods like mathematical modeling, statistics and algorithms to arrive at optimal or good decisions in complex problems. It is the discipline of applying appropriate analytical methods to help make better decisions.

The purpose of Operations Research is to elicit a best possible solution to a problem mathematically, which improves or optimizes the performance of the system. To achieve this result, analytical technologies such as simulation, optimization and probability and statistics are used.

The benefits of Operations Research, among many, are:

- * It gives insight into complex business problems

- * It improves business performance by improving decision making

- * Finds new opportunities to cost reduction

- * Compares the alternatives and aids in decision making

- * More accurate forecasting

- * Helps in better planning

- * Helps in pricing

- * Improving quality

- * Improving productivity

Total Productivity Maintenance :

Total Productivity Maintenance (TPM) is a maintenance program, which involves a newly defined concept for maintaining plants and equipment. Total Productivity Maintenance is an approach to optimize the effectiveness of production means in a structured manner. TPM focuses on improving the Planned Loading Time.

TPM brings maintenance into focus as a necessary and vitally important part of the business. It is no longer regarded as a non-profit activity. Down time for maintenance is scheduled as a part of the manufacturing day and, in some cases, as an integral part of the manufacturing process. The goal is to hold emergency and unscheduled maintenance to a minimum.

The most important objectives of TPM are:

- * Avoid wastage in a quickly changing economic environment.

- * Producing goods without reducing product quality.

- * Reduce cost

- * Produce a low batch quantity at the earliest possible time.

- * Goods sent to the customers must be non-defective.

The 8 pillars of TPM:

- * 5S-to reduce waste occurring during the implementation of a new machine or the production of a new product

- * Autonomous Maintenance-daily maintenance activities conducted by operators

- * Kaizen-focused improvement for eliminating waste

- * Planned Maintenance-for achieving zero breakdowns

- * Quality Maintenance-aims at zero loss by taking necessary measures to prevent it.

- * Training-for increasing productivity

- * Office TPM and Safety-for involvement of all parties

- * Health and Environment-for achieving zero work related accidents and for protecting it.

Types of Maintenance:

- * Breakdown maintenance

- * Preventive maintenance

- * Corrective maintenance

- * Maintenance prevention

Benefits of TPM:

- * Increase in productivity and OEE

- * Reduction in customer complaints

- * Reduction in the manufacturing

- * Reduced accidents

This course is designed to contribute to any company's continuous improvement initiative or need for decreased machinery downtime by stressing the importance of increasing Overall Equipment Effectiveness (OEE) and eliminating equipment-related wastes such as equipment downtime, equipment adjustments, unexpected downtime, planned downtime for equipment maintenance and time spent making nonconforming or defective parts. This course also emphasizes the importance of taking a more proactive approach in maintaining equipment, troubleshooting equipment-related product variations and increasing the uptime of the equipment under their control.

The courses covers the following topics:

- * The most common causes of machine downtime

- * How TPM minimizes machine downtime

- * TPM principles and their applications

- * How to calculate and interpret Overall Equipment Effectiveness (OEE)

- * How to create a TPM improvement plan

- * How to sustain a TPM system

Energy Conservation :

Energy conservation is the practice of decreasing the quantity of energy used while achieving a similar outcome.

Energy conservation is an important element of energy policy. In general, energy conservation reduces the energy consumption and energy demand per capita and thus offsets the growth in energy supply needed to keep up with population growth. Energy conservation facilitates the replacement of non-renewable resources with renewable energy.

Importance of energy conservation:

- * To decrease the demand of energy world-wide

- * Decreasing the need for nuclear power

- * Decreasing the need for scarce mineral resources

- * Decrease environmental pollution

- * To decrease the threat of global warming

- * Saving money

- * For better health and more pleasant environment

- * Decrease dependency on foreign energy sources

Various forms of energy:

- * Potential energy

- * Gravitational potential energy

- * Elastic potential energy

- * Kinetic energy

- * Thermal energy

- * Electrical energy

- * Magnetic energy

- * Electromagnetic fields

- * Chemical energy

- * Nuclear energy

- * Surface energy

The courses provides standards, measurement methods, technology and other support for a wide range of energy generation, storage, distribution and consumption of energy

Business Analyst :

Business analysis helps an organization to improve how it conducts its functions and activities in order to reduce overall costs, provide more efficient use of resources, and better support customers. It introduces the notion of process orientation, of concentrating on and rethinking end-to-end activities that create value for customers, while removing unnecessary, non-value added work. The person who carries out this task is called a business analyst or BA.

A Business Analyst works as a liaison among stakeholders in order to elicit, analyze, communicate and validate requirements for changes to business processes, policies and information systems. The Business Analyst understands business problems and opportunities in the context of the requirements and recommends solutions that enable the organization to achieve its goals.

The role of the Business Analyst includes, defining the scope of the business area, elicit requirements, analyze and document requirement, communicate requirements, identify solution, verify whether the solution meets the requirements.

ISO Lead Auditor Courses :

These courses are designed to train participants to perform external audits. These courses are also very useful for those who want to think like auditors.

Topics include:

- * Understand the application of the principles, procedures and techniques of auditing.

- * Interpreting the requirements and terminology

- * Viewing requirements from an auditor's perspective

- * Establish, plan and task the activities of an audit team.

- * Leadership responsibilities

- * Third-party issues

- * Conformity assessment techniques, auditing and follow-up

- * Audit planning and protocol development

- * Audit program design

- * Prepare and complete the audit report

- * Certified Lead Auditing requirements and responsibilities

Expert in TS 16949 :

ISO/TS 16949:2002, the technical specification, was approved and issued in March, 2002, as an automotive sector-specific QMS set of requirements which uses 9001:2000 as its base.

The training includes overview of ISO/TS 16949 including benefits to the organization, how an ISO/TS 16949 Quality Management System works, how the audit process works, an auditor’s role in ISO/TS 16949 Quality Management System.

CSQP :

Certified Software Quality Professional (CSQP) is an extensive training program for the software professional who want to develop their skills and competence in the field of Software Quality Management.

The course is aimed at improving the professional foundation for developing, controlling and improving the software quality and performances.

The course includes introduction to software quality management, software process, software testing, verification and validation, capability maturity model integration, software metrics and measurement, etc.

The course is highly recommended for people working in Software/IT, who want to develop capabilities to management quality and productivity in their departments with a much broader vision and skills.

Strike the right chord in Black Belt, Green Belt, Sigma Belt, six sigma courses, Six Sigma Training,6 Sigma Certification, Lean Mfg, SixSigma, Six Sigma Greenbelt, Six Sigma Belt Certification, Six Sigma Online Certification, Black Belt Certification, Green Belt Training, Master Black Belt, lean six sigma with IIEM.